ISO 9001:2015 CERTIFIED

We are among India’s Top Mechanical Seals and Rotary Unions Manufactures, using state-of-the-art technology. With many years of experience, our company holds the ISO 9001:2015 certification.

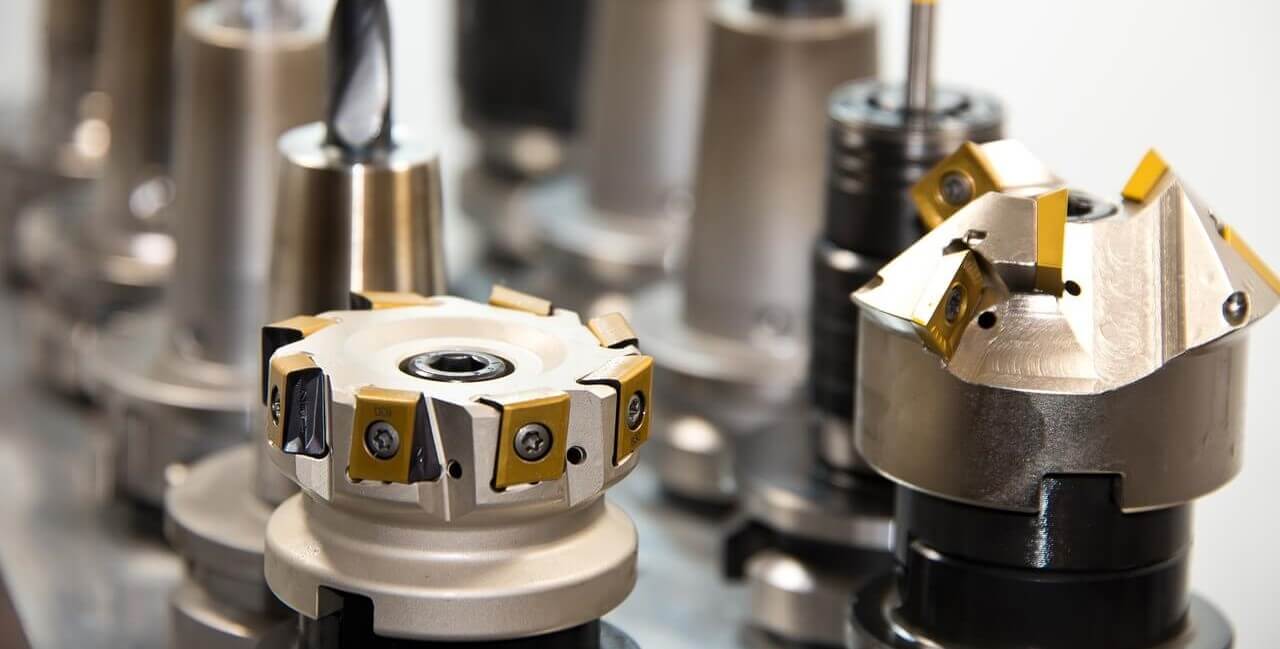

PRECISE TOOLS & MACHINERY

Utilizing state-of-the-art equipment and advanced machinery, our unwavering commitment is directed towards the optimal manufacturing of mechanical seals of unparalleled quality.

Dedicated Sales & Services

To foster enduring business relationships, Micrown Seals is dedicated to consistently delivering timely and appropriate sales and service responses, ensuring customer satisfaction.

Premium Export Quality

We engage in the international export of highly esteemed mechanical seals renowned for their exceptional quality across global markets.

WELCOME TO

Micrown Seals

TOP MECHANICAL SEAL MANUFACTURER IN INDIA

Micrown Seals, headquartered in Mumbai, India, stands as a leading manufacturer, supplier, and exporter of precision-engineered products. Our extensive catalog features a range of high-quality offerings, including Mechanical Seals, Sealing Components, Seal Support Systems, and Rotary Unions. Our diverse solutions span Pump, Pusher, and Non-pusher Mechanical Seals, as well as Single/Double, Balanced/Unbalanced Mechanical Seals, and Cartridge Mechanical Seals, showcasing our dedication to excellence in meeting varied industrial needs. We specialize in Agitator & Mixer Mechanical Seals, underscoring our commitment to providing top-notch solutions across a wide array of industrial applications. At Micrown Seals, we take pride in delivering reliable and innovative products to our valued customers.

Our product range comprises conical spring, single spring, multi spring, and wave spring mechanical seals. We offer mechanical seals in various configurations, including rubber bellow type, ptfe bellow, and metal bellow. Additionally, our selection of seal support systems encompasses the thermosyphon system, heat exchanger, and cyclone separator, all meticulously designed to enhance the performance and longevity of mechanical seals.

QUALITY ASSURANCE

CERTIFIED PRODUCTS

COMPETITIVE PRICE

OUR PRODUCTS

INDUSTRIES

Don't Just Take Our Words For It

Blair Mitchell

3rd Year With Us

Micrown Seals' commitment to excellence is unmatched. Their mechanical seals and support systems have seamlessly integrated into our processes, delivering outstanding results.

Piyush Kothari

1st Year With Us

Micrown understands the unique needs of various industries. Their rotary unions and joints have played a pivotal role in enhancing our production across the board.

Javed Shaikh

7th Year With Us

Our gratitude to Micrown Seals for minimizing downtime and conserving costs through their mechanical seal solutions.

And Many More

If you seek insights on how Micrown Seals can bolster your industry presence, reach out to us without delay!

FAQ

Mechanical seals are finely engineered devices used to seal entry or exit points of rotating shafts, preventing high-pressure fluid from leaking into low-pressure fluid. They also manage the seal environment and provide lubrication for secondary seals.

Mechanical seals play a pivotal role in centrifugal pump systems. These components uphold the integrity of pump systems by preventing fluid leaks and excluding impurities. Various types of Mechanical Seals encompass single and double mechanical seals, balanced and unbalanced seals, pusher seals, non-pusher seals, cartridge seals, dry-running mechanical seals for agitators, mixers, reactors & blenders, split mechanical seals for agitators, mixers, reactors & blenders, mechanical seal face, ring, bushes & sleeves, supply systems, and bearing isolators.

Components of a mechanical seal encompass secondary static seals, V-rings, O-rings or wedges, a static seal or stationary component, a seal connecting the rotating component to the shaft, a spring member, metal bellows, and either multiple or single springs. Additional hardware includes gland rings, compression rings, collars, and shaft sleeves.

Mechanical seals can be categorized into several types. However, the primary classification is based on a fundamental criterion – balanced type mechanical seals and unbalanced mechanical seals.

Mechanical seals are categorized based on a wide array of configurations and arrangements. This extensive diversity of seal types arises from the myriad applications, each involving distinct machinery, fluids, and processes.

In a pump’s mechanical seal, fluid is contained within a vessel as a rotating shaft moves past a stationary housing or when the housing rotates around the precise shaft.

The fundamental classifications of mechanical seals encompass balanced seals, unbalanced seals, and pusher seals.

A mechanical seal functions to prevent the fluid utilized by a machine from leaking into the surrounding environment.